Part of the difficulty in engineering a functional

bolt was nesting the Bulldog far enough into the Steyr receiver to achieve

the proper barrel alignment, while still retaining enough of the bolt

to allow attachment and rotation of the sleeve and cocking lever.

When placed in the proper position, the Bulldog occupies most of the

bolt cavity.

Even after I cut and trimmed the bolt and attaching

sleeve to the limit of their ability to grip each other, the Bulldog's

frame was still too large to recess up into the receiver far enough.

I found that the Bulldog's upper frame would have to be milled to fit

properly with the functioning bolt.

The real question was, what did the propmaker on

the film do, or perhaps, if I were in his shoes, what would I have done?

If the gun frame were to be modified heavily, would it still

be safe? Ultimately, I concluded the following:

The hero gun was to be a blank firing move prop.

Once modified, the underlying revolver would never be asked to

fire "live" rounds again. Blank rounds would reduce the compression

load to the gun and its frame considerably. Thus, all I really

would have needed to worry about was the gun’s ability to withstand

blanks. So I concluded milling down the frame should be a safe

change.

Trimming the upper cylinder support of the frame

should not weaken the revolver by much, if any, and any reduction in

strength would be more than compensated for by the lessened shock of

the blank rounds.

So, I proceeded to mill the top of the frame down

almost to the depth of the Bulldog’s rear sight groove. The sides

were then milled to the width of the hammer slot at the rear of the

frame.

These modifications were necessary to retain sufficient

the bolt material that a tube fitted to the turned down end would still

have enough circumference to grip the rod under it. The cocking

lever could then be fastened to this tube, which would in turn rotate

around the rear of the bolt as the lever is raised. By capping

the bolt just behind the lever and sleeve assembly using a casting of

the Steyr bolt end cap (with attachment provided by a small 4/40 Allen

screw), the bolt could be opened and pulled back with the same action

as the original Steyr rifle.

The final step in nesting the Bulldog beneath the Steyr was to

mill a round cut into the bolt for the length of the Bulldog’s replacement

barrel. I was able to use one of the scope mounting holes of

the Steyr receiver to establish a range of travel by threading a longer

set screw that extended into the milled slot, thereby controlling the

slide of the bolt and also setting its stopping point. This guide

screw then also doubled as a retaining screw to keep the bolt in the

receiver

The final step in nesting the Bulldog beneath the Steyr was to

mill a round cut into the bolt for the length of the Bulldog’s replacement

barrel. I was able to use one of the scope mounting holes of

the Steyr receiver to establish a range of travel by threading a longer

set screw that extended into the milled slot, thereby controlling the

slide of the bolt and also setting its stopping point. This guide

screw then also doubled as a retaining screw to keep the bolt in the

receiver

The stunt prop had a gun barrel that looked simply

like a heavy tube. There are no identifying marks nor any  evidence of the characteristic tapering of the standard Bulldog barrel.

We have concluded that the propmaker probably cut off the front

sight from the tapered Bulldog barrel and then covered it with an aluminum

sheath. He may have cut a matching (female) taper into a longer

aluminum tube; or he may have turned down the tapered barrel to a cylindrical

barrel and then fitted a tube over it to avoid having to deal with the

taper. It is equally possible that a Target model Bulldog was

used (although this is a less common gun), which is constructed in this

very fashion from the factory. The Target model came with a heavy

aluminum sleeve manufactured to a close tolerance slip fit over a thin

steel barrel. The aluminum sleeve included a shroud around the

ejector knob and was held in place on the steel liner barrel with a

tiny set screw.

evidence of the characteristic tapering of the standard Bulldog barrel.

We have concluded that the propmaker probably cut off the front

sight from the tapered Bulldog barrel and then covered it with an aluminum

sheath. He may have cut a matching (female) taper into a longer

aluminum tube; or he may have turned down the tapered barrel to a cylindrical

barrel and then fitted a tube over it to avoid having to deal with the

taper. It is equally possible that a Target model Bulldog was

used (although this is a less common gun), which is constructed in this

very fashion from the factory. The Target model came with a heavy

aluminum sleeve manufactured to a close tolerance slip fit over a thin

steel barrel. The aluminum sleeve included a shroud around the

ejector knob and was held in place on the steel liner barrel with a

tiny set screw.

Unfortunately, even the Target model barrel is

a little short, so the propmaker still would have had to take an aluminum

tube or rod and machine it to fit over the rifled steel core.

Either way, the sleeve used would provide the needed metal to drill

and tap into for the Steyr receiver mounts and for the front ammo housing

bolt that screwed into the underside of the barrel. As a bonus,

these same screws could also help hold the outer sleeve onto the steel

liner by extending through the aluminum and set contacting the steel.

Of course, the 6/32 Allen screw serving as a front sight detail on the

Steyr could also have served this purpose

From study of the stunt props I determined that

the original prop barrel was 0.75-inch in diameter with a 500-thousandths

(.50 caliber) bore, so I used 3/4-inch acrylic tubing having 1/8-inch

wall thickness for the model’s barrel. The 60-thousandths bore oversize

relative to the .44 caliber barrel of the Bulldog gives a bit

of extra clearance.

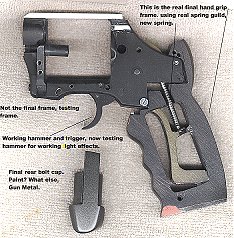

Once all of the test fitting had been worked out,

I proceeded to fabricate the prototype bolt from aluminum and to retool

the best of the primary gun components. Each part was checked

and rechecked to insure all would fit together and work in concert,

while maintaining the highest level of detail and premium finish achievable.

Molds and casts were made for each integrated Bulldog

component: the triggers, hammer, cylinder, cylinder swing arm (also

known as the crane), and a modified thumb latch from the Bulldog.

Similarly, molds and casts were completed for the

Steyr action, including the bare receiver, bolt end cap, ammo housing,

.222 ammo clip (also known as the magazine), and the trigger guard.

Note that the trigger guard and housing are one piece on the

original Steyr, but they were separated into two components to create

the hero prop gun.

The

rest of the detailing for the master patterns had to be fashioned by

cutting up one of my existing stunt copies for the basic shapes and

details, followed by extensive recreation and sculpting of finer details

and features

The

rest of the detailing for the master patterns had to be fashioned by

cutting up one of my existing stunt copies for the basic shapes and

details, followed by extensive recreation and sculpting of finer details

and features

The master pattern for the left side cylinder cover

was made using aluminum tubing and Bondo ®. The right side was made

from three side cover castings cut and enlarged to fit, with a cylinder

clearing carved out of the underside.

I worked very carefully on these details, using

the best stunt prop casting as a guide. Each master part was crafted

to match the fit of its companion on the stunt prop paying particular

attention to the placement of the side covers relative to details visible

on the Bulldog frame. The side covers were adjusted to match

every detail and fit on the master as compared with the solid cast stunt

prop, such as the partial covering of the trigger pins. Every aspect

was checked and rechecked to achieve a precise match.